LABORATORY

Virtual engineering and digital manufacturing – Industry 4.0

SECTION FOR DESIGN, VIRTUAL AND PHISICAL VALIDATION OF MECHATRONIC SYSTEMS

PROJECT BG05M2OP001-1.001-0008 | NATIONAL CENTER OF MECHATRONICS AND CLEAN TECHNOLOGIES

Manager: prof. DSc eng. Georgi Todorov

Contacts

e-mail: gdt@tu-sofia.bg

tel. +35929652574

The Section performs research related to integrated design and engineering methods using physical and virtual prototyping in the product design process. The project activities are focused on solving multidisciplinary engineering problems and integrating different concepts for control systems. Actual methods and technologies for virtual prototyping are used, as well as available laboratory stands for testing and testing of physical prototypes. Potential partners and clients of the laboratory are research teams in the country and abroad with similar scientific interests, as well as industrial partners, manufacturers of various components for mechatronics.

ACTIVITIES

Section team works projects in design, virtual and physical validation of mechatronic systems and products.

- Research and Development of mechatronic products;

- Multiphysics engineering analyzes and simulations using virtual prototypes;

- Impact tests on physical prototypes, including: impact test, free-falling object test;

- Tests for the impact of the working environment, including: for penetration of solid particles, temperature, UV radiation;

- Study of the physico-mechanical and tribological characteristics of lubricants.

SERVICES

- Research and Development of mechatronic products.

-

Engineering analyzes and simulations of products using a virtual prototype:

-mechanical structural analyzes;

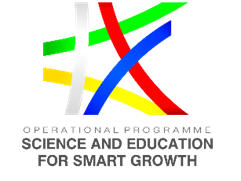

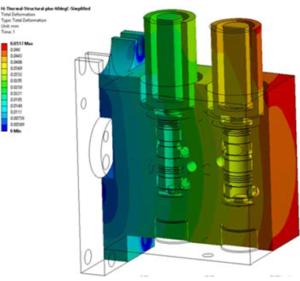

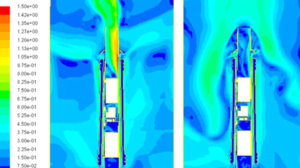

-fluid (CFD) and thermofluid analyzes;

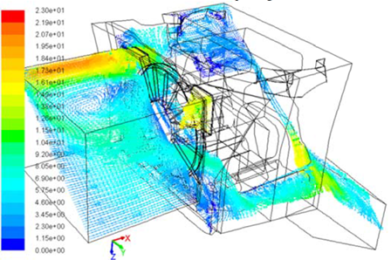

-multiphysics analyzes. -

Physical tests over products and components:

-shock tests;

-free-falling object tests;

-dust and moisture protection tests;

-climate chamber tests;

-tests with UV radiation. - Determination of physico-mechanical and tribological characteristics.

- High speed processes analyzes.

EQUIPMENT

The Section has the following equipment:

Specialized software for multiphysics engineering analysis ANSYS Multiphysics 19R3 - used to perform engineering analysis of various mechatronic products.

Thermofluid (multiphysics) analysis of automotive engine

Sructural mechanics analysis of piezo-electric actuator

Thermofluid (multiphysics) analysis of cooling module

Multiphysics analysis of telecommunication electronics

Complex for physical validation of mechatronic systems subjected to mechanical impacts - stands and devices for testing impact loads.

Impact test machine

Free-falling object test machine

Complex for physical validation of mechatronic and tribotechnical systems exposed to the working environment - a set of stands and devices for determining the influence of the working environment (temperature, dust, UV radiation), as well as for measuring tribotechnical parameters.

Dust chamber

Testing for wear and friction

High-speed camera - used to record fast-moving processes, including as a recording device when performing impact tests.