LABORATORY FOR MECHANICAL TESTS AND EXPRESS DIAGNOSTICS

Mechanical Tests Section

PROJECT BG05M2OP001-1.001-0008 | NATIONAL CENTER OF MECHATRONICS AND CLEAN TECHNOLOGIES

Manager: Assoc. prof. Rumen Krastev, PhD (Institute of Michanics – BAS)

E-mail: r_krastev@imbm.bas.bg

Phone: +359 889 701 105

The secton performs determination in a wide temperature range of mechanical characteristics in static and dynamic tests; crack resistance characteristics; mechanical behaviour under impact load. Potential partners and clients of the laboratory may be research teams with similar research interests and organisations engaged in the study of metal products.

ACTIVITIES

- Tensile tests of metallic materials

- Fatigue tests of metallic materials

- Fracture toughness tests

- 3-point bending tests and 4-point bending tests

- Characterisation of material properties at high rates using a split Hopkinson (Kolsky) pressure bar

- Data treatment and analysis

- Consultations

SERVICES

- Tensile test at room temperature - EN ISO 6892-1:2020

- Tensile test at high temperature - EN ISO 6892-2:2018

- 3-point bending (flexure) test

- 3-point bending (flexure) test

- Hopkinson (Kolsky) bar experiments

- Assistance in making samples of the required dimensions

- Consultations

- Strain controlled fatigue test - ASTM E606/E606M-21

- Other standard or non-standard material tests, depending on the capabilities of the equipment and the research team.

EQUIPMENT

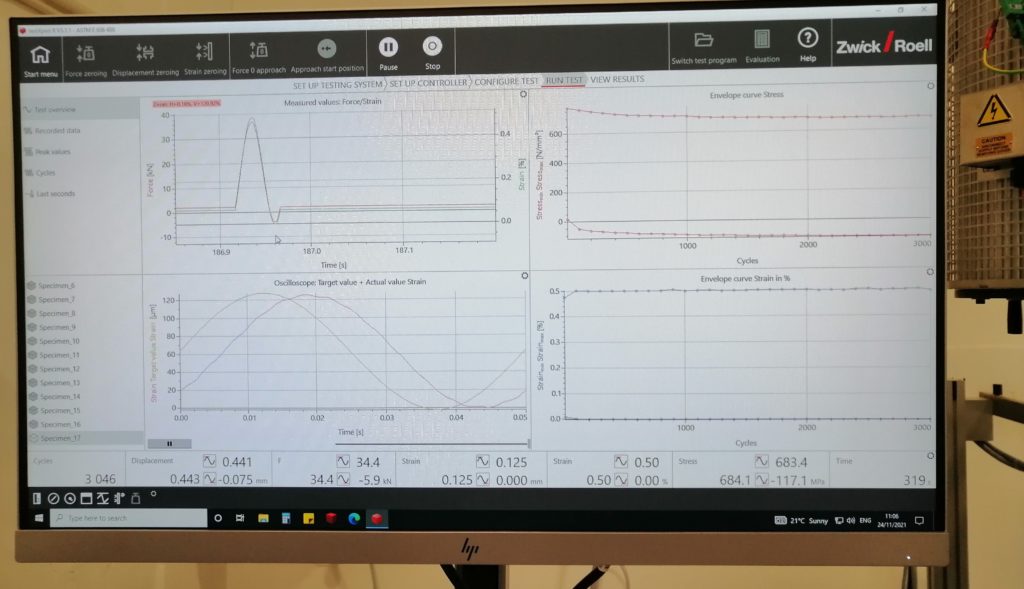

COMPLEX FOR DETERMINATION OF MECHANICAL CHARACTERISTICS IN STATIC AND DYNAMIC TESTS ZWICK/ROELL, HA-250

The testing system is designed to determine material properties in several conditions. The specimens are loaded via test quantities force, bending moment, or deformation with defined values, time sequence and frequency. Tests and with fracture or without fracture of the specimen, depending on the test method used. The test can be done with monotonically increasing (static) or cyclic (dynamic) loading. Typical tests are cyclic tension, compression or bending, based on various standards.

The complex for static and dynamic tests is located in the building of the Institute of Metallurgy, Equipment and Technologies (www.ims.bas.bg)

Specialised TestXpert III software is used when conducting static tests, and for dynamic tests, TestXpert R software is used.

Testing programs are introduced in the software according to the specified standards, and the software automatically calculates many parameters. The results report contains selected parameters.

The servohydraulic testing machine HA-250 is equipped with a high-temperature furnace (1000 oC) and a temperature chamber (-80oC to +250oC). The testing system is designed to perform the following tests:

- Static tensile tests on flat and round specimens (ASTM E8 / ISO 6892)

- Force range: up to 100 kN

- Temperature: -80 up to 250oC (up to 220oC with clip-on extensometer)

- Static and dynamic 3- and 4-point bending tests

- Force range: up to 100 kN

- Temperature: -80 up to 250oC

- Easy adoption of bending fixtures on top of the hydraulic grips.

- Low cycle fatigue tests on threaded specimens (ASTM E606)

- Threads: M8, M10, M12, M14, M16

- Temperature: 200 – 1000°C

- Fracture toughness tests acc. to ASTM E399, ISO 12135, ASTM E1820

- Geometry: 1″ (W/B ratio = 2)

- Temperature range: -80 up to 220°C

SPECIMEN REQUIREMENTS

Preferred dimensions of tensile test specimens for extensometer with 25 mm gauge length

- Cylindrical machined specimens, ISO 6892, test diameter Ф5, linear section 30 mm, rounding R = 16 mm and total length 150 mm.

- Flat dumbbell-shaped specimens with a cross-section of 4×20 mm, linear section 30 mm, rounding R = 20 mm and a total length of 170 mm.

Other specimen types

Contact us to specify the dimensions of specimens according to other standards, non-standard specimens (thickness up to 9 mm, diameter up to 18 mm) or specimens for bending, compression, fatigue, or crack growth rate.

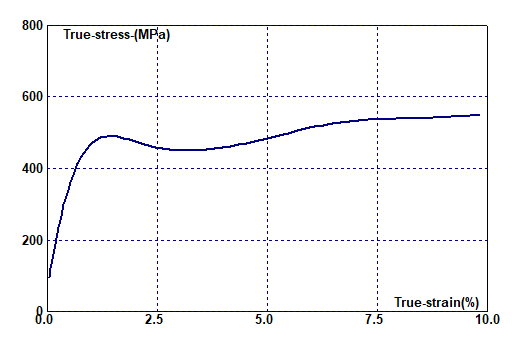

MATERIALS TESTING AT HIGH STRAIN RATE USING A SPLIT HOPKINSON (KOLSKY) PRESSURE BAR

The machine is used to determine the diagram of elastic and plastic deformation under pressure at a high strain rate. Consecutively, we can determine the elastic modulus, yield strength (if applicable) and compressive strength. The maximum stress and maximum deformation depend on the selected impact conditions (mass and velocity of the striker).

The system consists of 3 bars made of high-strength steel with a 20 mm diameter. They are mounted on plain bearings and are movable in the longitudinal direction. The test specimen is cylindrical with recommended dimensions of 5 or 8 mm in diameter and 5 or 8 mm in length. The sample is located between the first and second bars. Strain gauges are glued in the middle of them. There is equipment for acquiring the strain in the middle of the bars with one million records per second sample rate. There are four strikers with a length between 200 mm and 800 mm and a device for firing a selected striker with compressed air. There is a computer for data recording and processing.

Indicative requirements and conditions

- Samples with a cylindrical shape, 5 or 8 mm in diameter and 5 or 8 mm in height, shall be tested. Recommended size: d = 8 mm, h = 8 mm.

- Impact speed: up to 28 m/s. Recommended speed: 15 m/s.

- Dimensions of the available strikers: 200, 400, 600, 800 mm. (Weight from 0.5 kg to 2 kg). Recommended size: 400 mm.